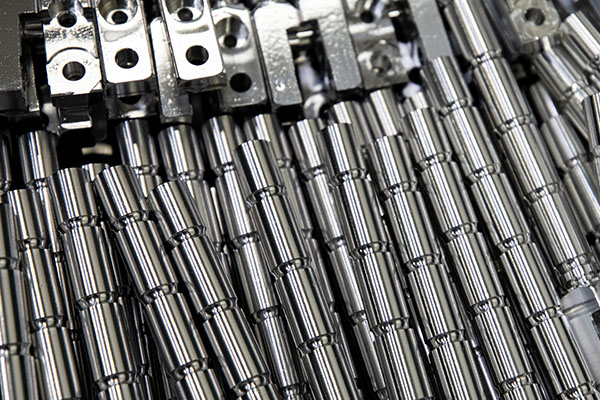

Lathe Centers

CNC Turning

During the CNC turning process, we use lathes with auto bar feeders to make parts ranging in size from .25” – 25” in diameter and up to 80” in length.

Subtraction Machining

CNC Turning Services

Unlike other cutting styles where the tools themselves move and spin, in the CNC turning process, the raw material is spun at high speed and a cutting tool shaves away away the substance from the workpiece. CNC turning can be used to create a variety of products including tubing, couplings, rivets, fasteners, shafts and much more.

At MMT, we use six CNC lathes with auto bar feeders ranging in various sizes for different applications. With them, we can produce a wide range of parts ranging in size from .25″ to 25″ in diameter up to 80″ in length, and our machines can handle tolerance as close as .0003 inches.

Our lathes and turning centers include straight turning, taper turning, external grooving, threading, knurling, boring, and drilling.

CNC Turning Machine List

Haas SL-30T (x3)

Haas SL-20T (x2)

Haas SL-40L

Cincinnati Engine Lathe

What can we make for you?

Request a Quote for

CNC Turning

No matter the size of your business or the industry you serve, we can fulfill a single-part prototype or 1,000+ piece order, polish it to a perfect cosmetic finish, and get it to you on time…without the worry of shotty quality standards. We know you’ve been let down too often before with missed deadlines and average customer service.

We are here to change this.