Ultra Precise

Swiss Screw Machine Services

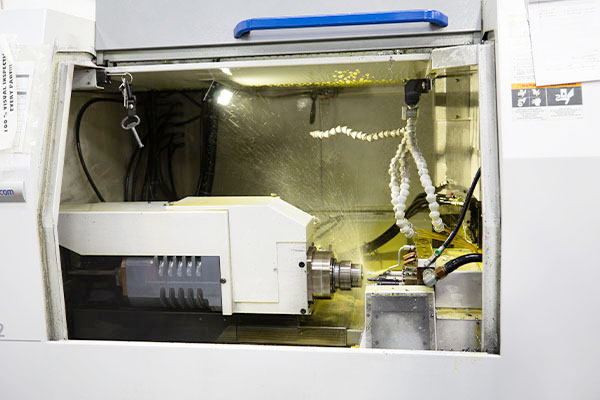

Housed inside our 77,000 sq. ft facility, our Swiss screw machine services are performed by eight Swiss turning lathes and five conventional CNC lathes to cover any project that requires the ultimate in precision.

Acurate and Consistent

CNC Swiss Screw Machining Capabilities

Our Swiss machining delivers small, high-precision parts necessary for manufacturing critical components. These machines are perfect for close tolerance and complex parts since they can run different grades of metal and plastic.

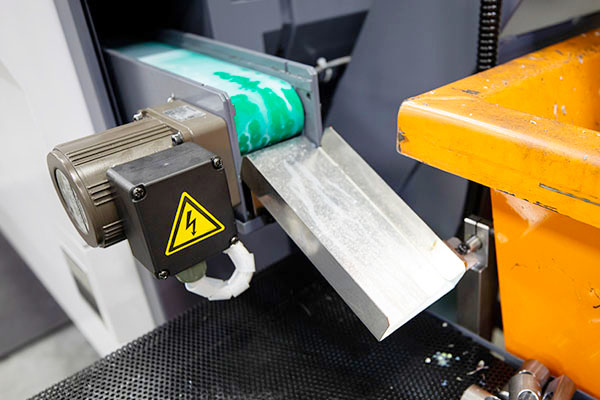

Unlike other types of screw machines, Swiss machines generate the features of the part by moving the material and the tool simultaneously. With them, we can produce your parts with more accuracy and less downtime, allowing you to keep production on track.

This flexibility allows us to explore different options to improve performance and reduce cost, while achieving a high level of detail.

Swiss Screw Machine Advantages

1/16 “ to 1 1/4 “ with available part materials in brass, steel, copper alloys, exotic stainless alloys and stainless steels.

Swiss Screw Machine List

Our 13 Citizen Swiss turn lathes with auto bar feeders range from 7- to 12-axis capability for the manufacturing of parts up to 1.25″ in diameter.

Swiss CNC LatheCitizen L32 (x6)

Swiss CNC LatheCitizen A20 VII (x4)

Swiss-type lathe with auto bar feeder.

Swiss CNC LatheCitizen A32

Swiss-type lathe 32mm with auto bar feeder.

Swiss CNC LatheCitizen M32

Swiss-type lathe with 12-axis, 10-position turret and auto bar feeder.

Swiss CNC LatheCitizen BNJ51

What can we make for you?

Request a Quote for Swiss Screw Machine Services

No matter the size of your business or the industry you serve, we can fulfill a single-part prototype or 1,000+ piece order, polish it to a perfect cosmetic finish, and get it to you on time…without the worry of shotty quality standards. We know you’ve been let down too often before with missed deadlines and average customer service.

We are here to change this.